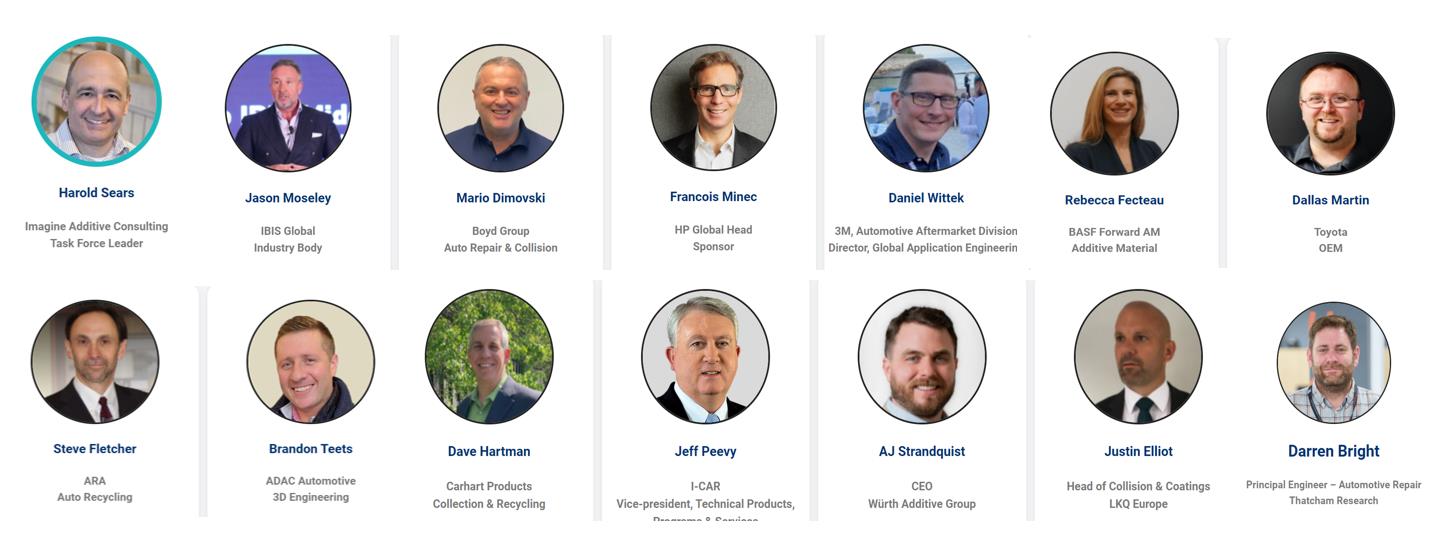

IBIS Worldwide, in collaboration with its supporting partners, announced at IBIS USA 2023 in Nashville the formation of a task force dedicated to exploring the use of 3D printing in automotive repair and the collision industry. The goal of the task force is to identify opportunities for using 3D printing to improve the efficiency and effectiveness of automotive repair. This could include using 3D printing to create replacement parts, tools, and other components, as well as using the technology to improve the design and manufacture of existing parts.

Task force lead Harold Sears and Mario Dimovski visited HP in Barcelona to see the latest in 3D printing technology.

We are pleased to present our report of the 3D Printing in Collision Repair Task Force, showcasing our findings in exploring and advancing the integration of 3D printing technologies within the automotive and collision repair industry. This report provides an overview of our initiatives, key highlights, and initial recommendations. Our efforts have been focused on engaging with industry stakeholders, conducting research on 3D printing applications, and identifying key areas for improvement.

The report also addresses the risks associated with using poor quality 3D-printed auto parts and proposing a framework for a regulatory body to endorse and monitor the use of 3D-printed automotive parts. The industry’s collaboration and support have been instrumental in driving our progress, and we look forward to continued success in the upcoming quarters.

3D Printing in Collision Task Force